Views: 235 Author: Reshine Display Publish Time: 2023-12-18 Origin: Site

TFT displays are increasingly being used in outdoor applications such as automobile displays, digital signage, and kiosks. High ambient light in outdoor environments frequently results in a washed-out image, rendering the screen unreadable. The readability and durability of TFT displays in direct sunlight are becoming increasingly important. For many years, Reshine Display has been developing sunlight-readable LCD solutions. The company is well-versed in the intricacies of sunlight-readable TFT LCDs. Before we get into how to make an LCD sunlight-readable, let's define visibility.

Visibility is the ease with which a viewer can detect an object, or, to put it another way, the relationship between luminance contrast and the threshold of the human eye. As a result, the higher the contrast of an object, the better its visibility.

To be readable in an outdoor environment with very bright ambient light, the brightness of the LCD screen must be greater than the intensity of light reflected from the display surface. To be viewed comfortably by human eyes, the LCD's brightness must exceed its reflected light by at least a factor of 2.5. Naturally, there are two approaches to making an LCD sunlight-readable: increasing brightness or decreasing reflectance.

The ambient brightness on a clear day in direct sunlight is approximately 6000 cd/m2. A typical TFT LCD with a touch screen reflects approximately 14% of ambient light or approximately 840 cd/m2. Most LCDs nowadays use an LED backlight as a light source. It is not difficult to increase the brightness of an LCD to 800 1000 Nits to overcome the bright reflected sunlight. As a result, you have a TFT LCD that can be read in direct sunlight. This method, however, necessitates the use of more backlight LEDs and/or a higher driving current. High power consumption, increased heat dissipation, increased product size, and a shorter LED backlight lifespan are the drawbacks. Increasing the backlight to make TFT LCDs visible in direct sunlight is not a good solution. Click here for TFT LCD Display.

A reflective TFT LCD has both transmissive and reflective properties. Between the LCD and the backlight, a partially reflective mirror layer is added. This modification incorporates some of the reflected ambient light into the LCD's display. A light source, on the other hand, increases the brightness of the TFT display. A transflective TFT LCD, on the other hand, is more expensive than a transmissive lighting one. Simultaneously, the partially reflective mirror layer will block some of the backlight, making it unsuitable for indoor or low-light environments.

What causes light to reflect? When light passing through one transparent medium encounters a boundary with another transparent medium, some of the light bounces off the border. We can calculate the amount of reflected light using the most basic version of Fresnel's equation.

R=[(n2-n1)/(n2+n1)]2 (n1 and n2 are the indexes of refraction for the first and second materials)

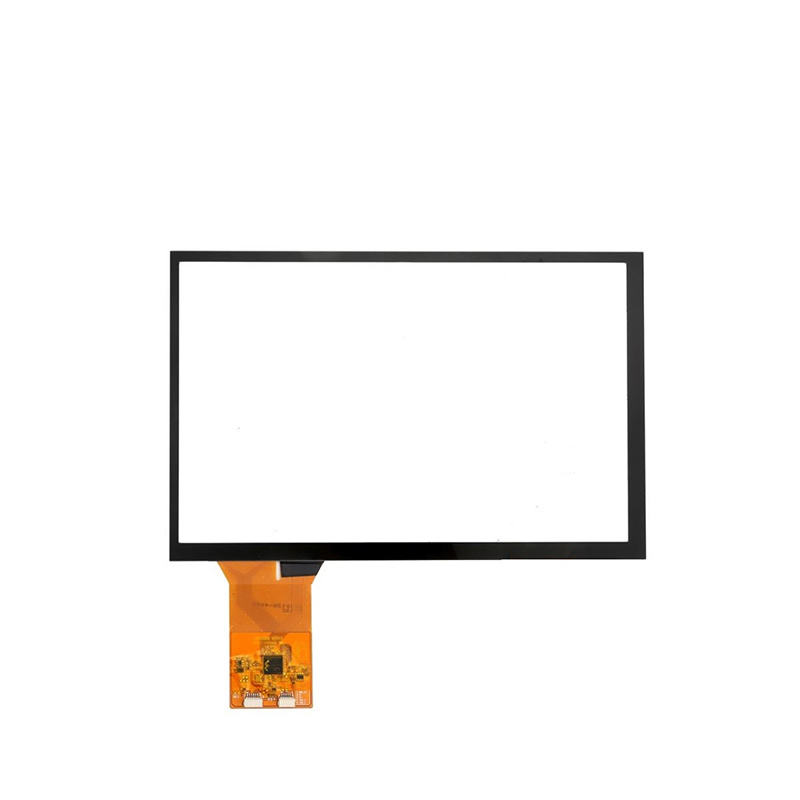

The equation clearly shows that the greater the difference between two materials, the more light is reflected. TFT LCDs with touch panels are known to have layers of structure. Light reflection occurs in a variety of locations.

The sum of reflected light on any interface where two materials meet is the total reflectance on a TFT LCD with a touch panel. For example, the difference in the index of refraction between the polarizer and display glass is very small, around 0.1. As a result, the reflected light at this interface is only 0.1%. As Fresnel's equation suggests, we should concentrate on reducing reflections at air interfaces. The index of refraction of air is one, while that of glass is 1.5. As a result, the reflectance is 4.5%. As a result, the three air interfaces contribute roughly 13% of the TFT LCD's reflectance.

Using an anti-reflection and anti-glare film or applying an AR coating is the quickest and easiest way to reduce air-glass interface reflectance. An external film with AR properties reduces reflected light while also providing additional benefits.

Shattering glass is a serious issue in the food industry. This problem is easily solved by using an LCD screen with an external film. In terms of automotive applications, in the event of an accident, a broken LCD with top AR film will not produce sharp-edged glass that could harm the vehicle occupant. Nonetheless, a top film always reduces the surface hardness of a TFT LCD. It is also prone to scratches. AR coating, on the other hand, preserves the LCD's hardness and touch performance. However, it is more expensive.

TFT LCD top layer reflectance can be reduced by 23% using the above measurements.

Attaching a linear polarizer to the top of the TFT screen is another quick and easy way to address reflectance. Only half of the light that reaches the top polarizer passes through. As a result, the reflection light is cut in half. This is a very low-cost method of increasing the contrast of a TFT LCD, making it more sunlight-readable. Again, any film on top will reduce the surface hardness of the LCD, and a polarizer will reduce transmission. Those aren't very good.

A circular polarizer laminated on a TFT LCD will eliminate a significant amount of reflectance. Because ambient light becomes circularly polarized when it passes through a circular polarizer. The polarization direction flips by 180 degrees when it is reflected. As a result, nothing passes through the viewer's eyes when reflected light returns to the circular polarizer.

For an LCD with a resistive touch panel, this method is extremely effective. We already know that resistive touch LCD has two air gaps: one between two ITO layers and one between the touch panel and the LCD display. The reflection caused by the two air gaps is extremely strong. A circular polarizer is used to block out the majority of the reflected light, making the LCD display sunlight-readable.

The cost of such a solution is a disadvantage. Because we need both a circular polarizer and a retarder film on the top of the LCD, we must ensure that light from within the LCD is not blocked by an external circular polarizer.

The primary cause of poor sunlight readability is air gap reflection. This can be improved in two ways. Apply AR films to both internal air gap interfaces. The add-ons can reduce the reflection in this area from 8.5% to 2%. And because the AR films are not exposed to the elements, they are much less expensive than those used outside. Maintaining the air gap also ensures ease of service if either the touch panel or one of the LCDs needs to be repaired.

Using optical bonding to eliminate the air gap is the most effective method. In layman's terms, we fill the air gap with a special optical adhesive to smooth out the refraction index differences in the area. As a result, the reflectance caused by internal air gaps decreases from 8.5% to 0.5%. Optical bonding is a costly but effective method of improving TFT LCD sunlight readability. It improves durability and impact resistance. Furthermore, no air gap means no condensation or fogging.

There are numerous methods for making TFT LCDs sunlight-readable. They all have advantages and disadvantages. Topway has over 20 years of LCD design and manufacturing experience and knows how to create the best sunlight-readable TFT LCD for difficult environments. Send us a message and we'll get started on developing a suitable sunlight-readable TFT LCD for your project.

Boosting Urban Mobility: Making Public Transport the Go-To Choice in Your City

How Do You Troubleshoot Common Issues with MIPI LCD Displays?

What Are the Key Technical Specifications to Consider When Selecting a MIPI LCD Display?

What Are the Pros and Cons of Using LCD Displays for Gaming?

What Are the Environmental Impacts of Manufacturing LCD Displays?

How Does the Viewing Angle Affect the Quality of LCD Displays?